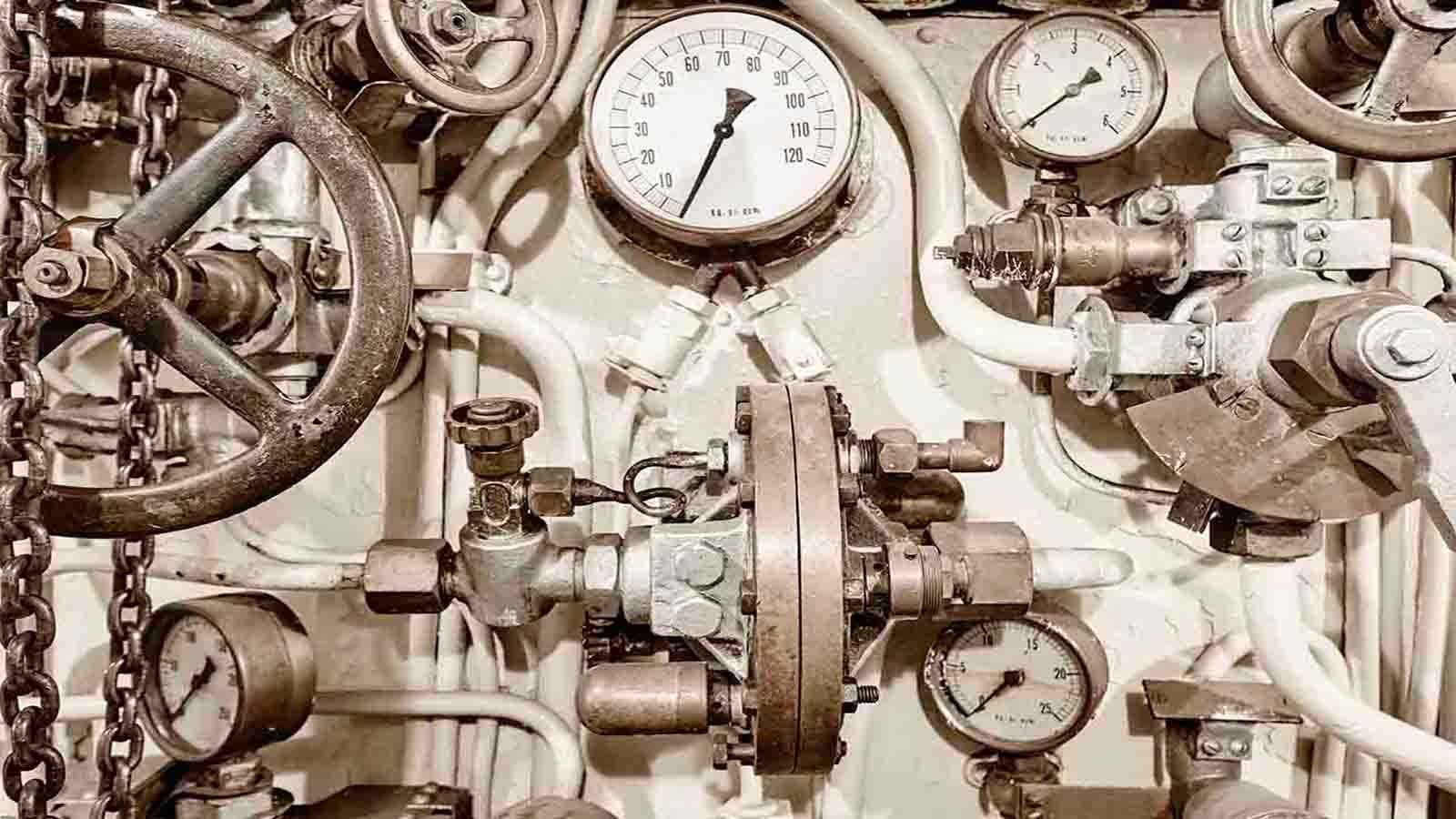

About the Program

The objective of this course is to provide the candidates the Detail knowledge and skills in Instrumentation Design discipline to facilitate faster learning curves while on the job.

This course is to provide basic knowledge and skills in this discipline of Instrumentation Design Engineering for Oil & Gas sector. This course will cover the fundamental principles and concepts used in Instrumentation Design & Detailing. Upon completion of this course, students will have a clear understanding of the design principles used in Instrumentation System Design for Oil & Gas Energy Sector.

The goal of this course is to provide delegates the Detail knowledge and skills into Design, Engineering, Construction, Commissioning operation & Maintenance in the field of Instrumentation Design Engineering for Oil & Energy Sector.

Learning objective

- Overview of EPC Industry and Scope.

- Role of Instrumentation Engineer in various types of

- Knowing Client requirements and collection of specific data for projects.

- Relevant Codes & Standards.

- Basic Design requirement based on the type of plant g. Chemical, Petrochemical, Pharmaceutical Industrial, power plant etc.

- Selection of Instruments for Controlling Flow, Temperature, level and Pressure.

- Vendor’s details and specification for all Instruments used to control Flow, Level, Temperature and

- Installation and maintenance Tips of all Instruments.

- Instrument Index, Instrument Location Plan Details

- Process Data sheets and Specifications, Instrument Data Sheets

- Instrument Wiring Layout, Logic Diagrams

- Loop Drawing, Loop Wiring Diagram, JB Layout

- Cable Schedule, Cable Tray Layout

- Hook-Up Drawing

Program Highlights

About The Course

Course Modules

- Introduction to oil and gas industry & EPC contracts

- General Industry overview and basic concepts

- Oil and gas prospecting(exploration)

- Oil and gas production facilities

- What is an EPC contract

- The tender & procurement process

- The scope of works

- Hazardous Areas

- Definitions

- Introduction: explosion consequences

- Classification system: sources of release and zoning

- Classification of apparatus: grouping and temperature

- Instruments and instrument symbols

- Hazardous Definition for instruments system

- Hazardous is of classification

- Hazardous analysis, hazardous operation

- Hazardous identification

- Concept of the group, div, zones and classes, temperature, explosion triangle and mode of safety

- Introduction to process measurement

- Basic measurement concepts

- Definition of terminology

- Measuring instruments and control valves as part of the overall control system

- Pressure Measurement

- Principle of pressure measurement

- Pressure transducers and elements

- Level Measurement

- Principles of level measurement

- Simple sight glasses

- Hydrostatic pressure

- Ultrasonic measurement

- Electrical measurement

- Density measurement

- Temperature Measurement

- Principles of temperature measurement

- Thermocouples

- Resistance Temperature Detectors (RTD’s)

- Flow Measurement

- Principles of flow measurement

- Open channel flow measurement

- Oscillatory flow measurement

- Magnetic flow measurement

- Positive displacement

- Ultrasonic flow measurement

- Mass flow measurement

- Control Value Essentials

- Introduction to control valve theory

- Different types of control valves

- Characteristics

- High-pressure drop applications

- Sizing of control valves, actuation and essential accessories- Examples of high

-pressure drop applications

– Actuators

– Petitioners

– Pneumatic circuits

- Control Valve Material, Standards, Applications, Maintenance and Installation

– Materials

– Quality Standards

– Severe Service Applications

– Pressure Relief Valves

– Installation and Maintenance - ESD and F&G Emergency Shutdown Logics (ESD)

- Input & output measurement standards

- ESD (Emergency Shutdown Logics)

- I/O type, operation and applications Fire & Gas (F&G)

- Basics of fire & gas (F&G) system

- Type of detector & alarm system

- Working principle of F & G system

- Instrumentation standards in oil and gas, E & I drawings and documentation

- Plant documentation

- The role of plant documentation, standards and specifications

- Drawing Types and Standards

- Standards organizations (ISA, IEC, ISO)

- Understanding diagram layouts and formats

- ISO 9002 and document control

- API RP14F – Section 122 – electronic instrumentation

- ISA standards library for automation and control

- Specification forms – ISA S20 – specification forms for process measurement

- Instrumentation Drawings, Documentation & Schematics

- Instrument index sheet

- Instrument data/spec sheet

- Process data sheet

- Calculation and Sizing

- Input/output list

- Cable schedule

- JB schedule

- Conventional instrument field wiring

- Instrumentation drawings/layout

- Type of layout & drawing management

- Piping & instrumentation diagram (P&ID)

- Process flow diagram

- Logic diagram

- Loop diagram

- Hook-ups/isometric diagram

- Standard symbols & instrument legends

- Nomenclature

- Field wiring diagram

- Logic diagram

- Level sketch

- JB layout diagram

- Cable tray layout & routing diagram

- Instrument nozzle elevation drawing

- Control valve assembly

- Mounting layout (supports, anchors, sleepers & guides)

Course Certificates

SmartBrains is associated with The National Skill Development Corporation (NSDC) as the Training and Certification partner for various job oriented training programs across various sectors including Oil & Gas, Power, Renewable Energy, Hydrocarbon, IT & ITs, Electronics, Telecom, Agriculture, Life science etc. offering assessment based Training & certifications for a gamut of job profile.

Who should join?

- Working professionals in Domains: Site Engineering, .Construction & Commissioning operation & .Maintenance, Technicians in Process Engineering Field.

- Students (Chemical Engineering, Diploma in Chemical .Engineering) who want to develop their career in Design Engineering.

For Corporate queries

A-25, Sector-59, Noida (UP),India

Pin Code-201301

Connect with Program Advisor

training@smartbrains.com

+91 9891108002 | +91 9891108700

www.smartbrains.com

Nodal Centers

Noida, Dehradun

Guwahati, Pune